Industrial Solutions

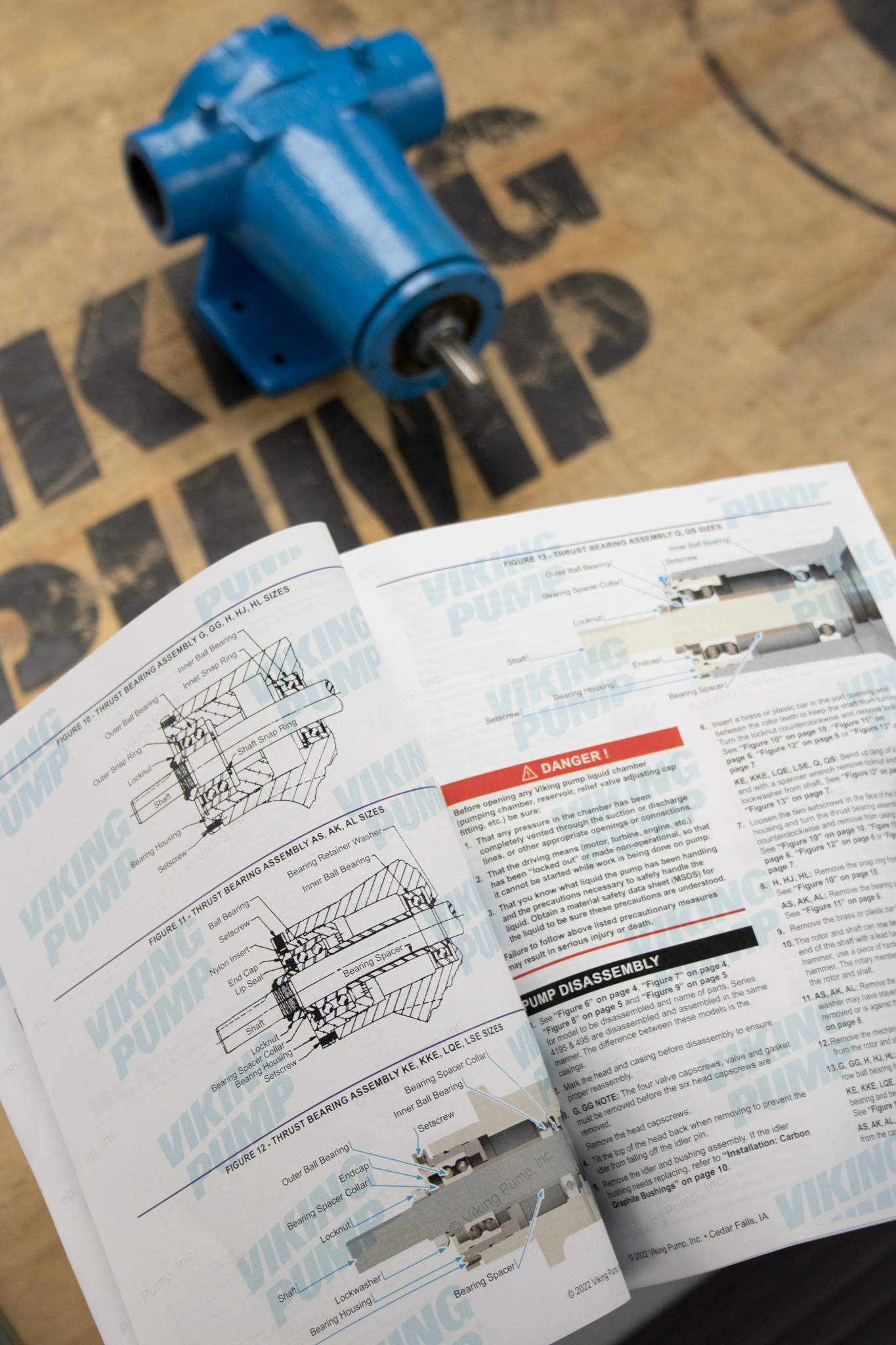

Viking Pump’s industrial gear pumps are the premiere positive displacement pump technology that covers nearly every pumping need.

With construction options that have been proven to work for light, medium, and heavy-duty applications, the versatility and popularity of positive displacement pumps lie in their relatively simple design, high efficiency, and consistent flow rates.

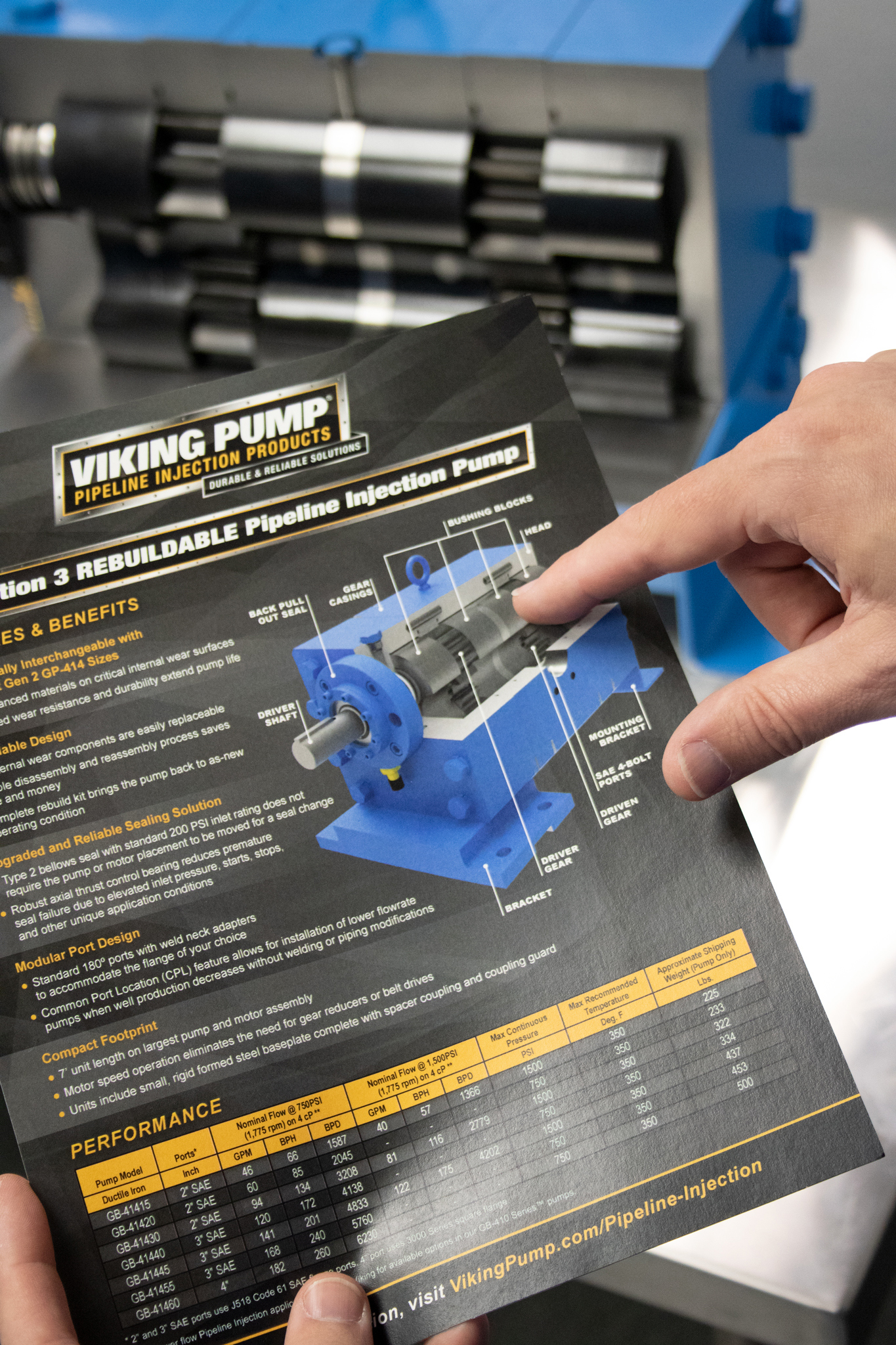

Energy Solutions

Viking's oil and gas pumps are used in almost every process where oil or oil derivatives are found. With the advancements in unconventional oil exploration and production, Viking Pump has created a series of products tailored for the upstream and midstream oil fields and specifically for LACT (Lease Automatic Custody Transfer) pipeline injection service as well as gas dehydration applications.

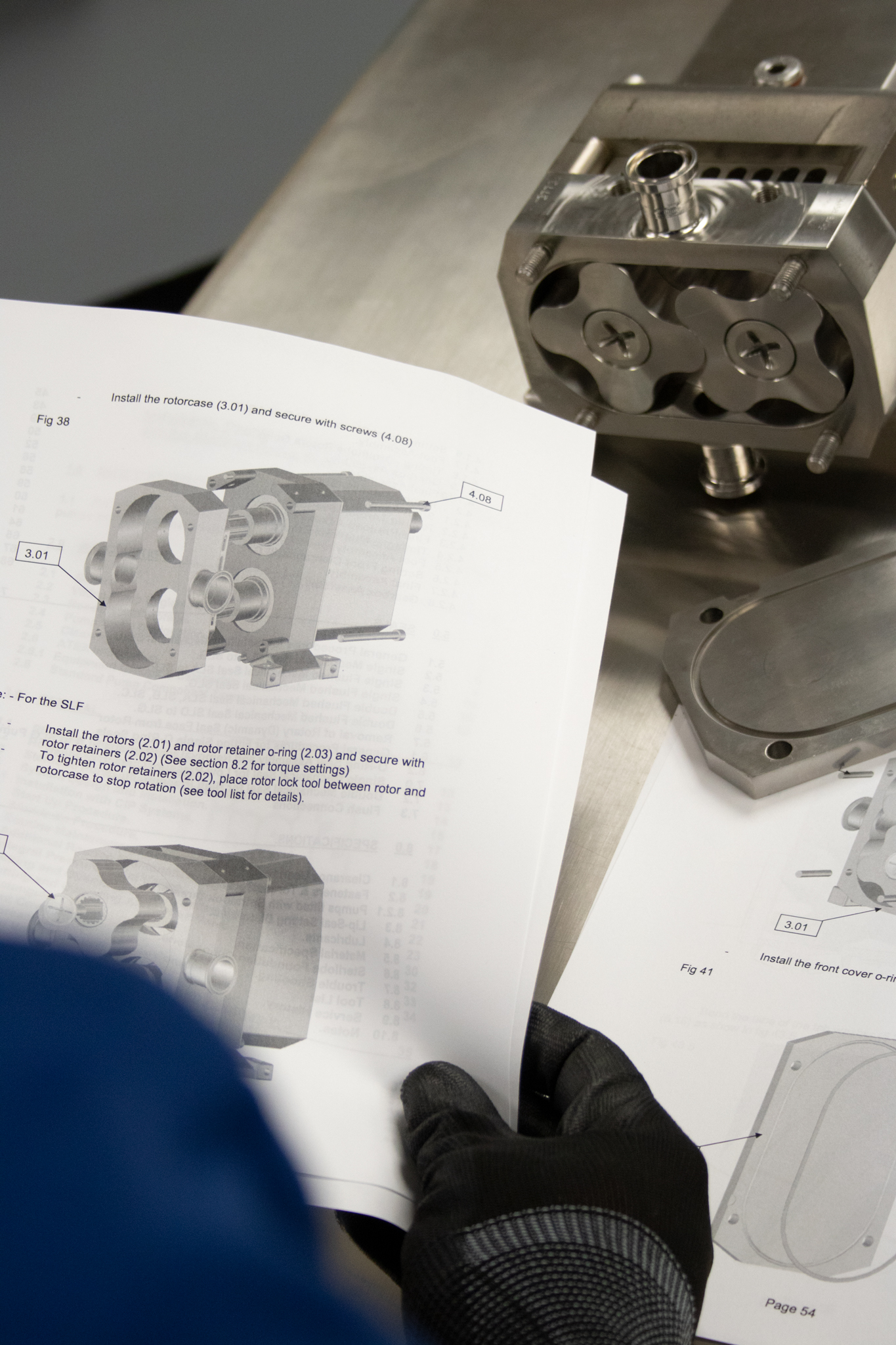

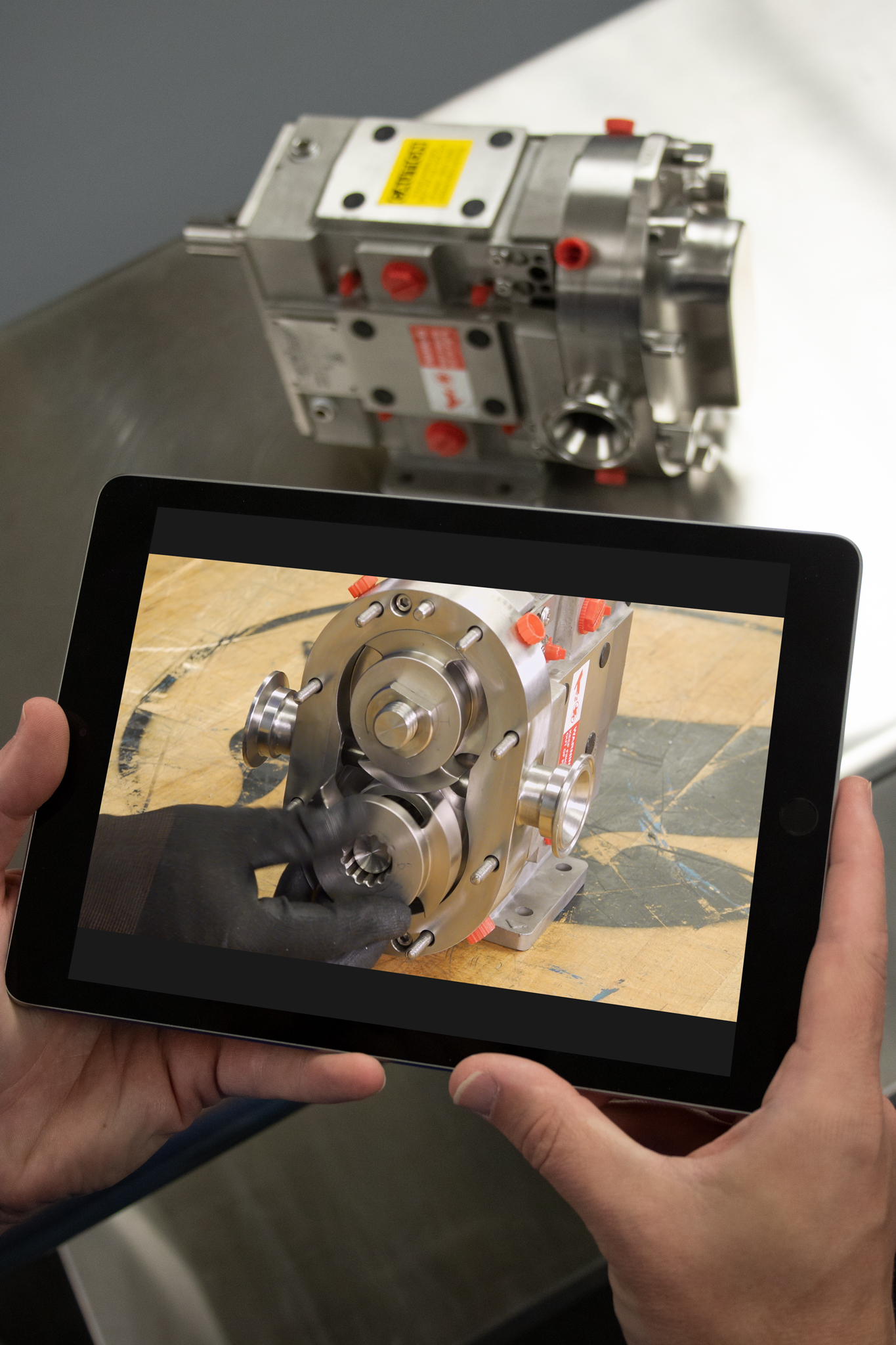

Hygienic Solutions

Viking Pump’s hygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reduce cross-contamination, we offer CIP (clean in place), SIP (sterilize in place), and COP (clean out of place) pumps to save you time and effort.